The Science Behind Solder Smoke and Its Impact on Workplace Air Quality

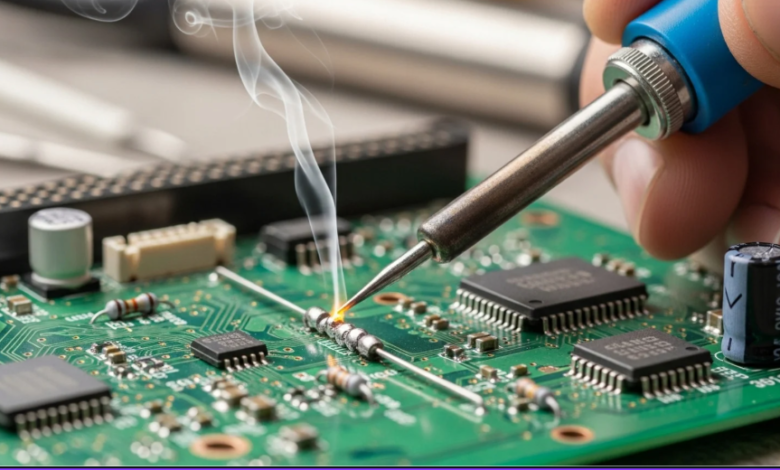

Soldering has become an essential process across manufacturing, electronics repair, and assembly lines. However, the byproduct, solder smoke, is more than just a nuisance. In the first few seconds of heating solder, microscopic particles and chemical vapors are released into the air, posing serious respiratory risks. Installing a solder smoke extractor is one of the most effective ways to prevent long-term health effects and maintain a compliant, safe work environment.

Understanding What Solder Smoke Contains

Before exploring its impact, it is important to understand what solder smoke actually is. When solder melts, it releases a combination of metal oxides, volatile organic compounds, and flux residues. These ultrafine particles can easily bypass the body’s natural filtration system, traveling deep into the lungs. Over time, consistent exposure can result in respiratory irritation, decreased lung function, and occupational illness.

Workplaces that rely heavily on manual or automated soldering processes often experience a concentration buildup of these contaminants. Without proper extraction, airborne particles can linger in the atmosphere, affecting not only soldering technicians but every individual working within the facility.

How Solder Smoke Impacts Air Quality

Solder smoke quickly disperses into the workspace if not controlled, reducing indoor air quality and increasing exposure levels. The particles are often invisible but hazardous. Prolonged exposure may contribute to inflammation in the respiratory tract and trigger symptoms such as coughing, dizziness, and fatigue. In high-volume operations, this can also lead to violations of workplace safety standards and regulatory air quality thresholds.

The Role of Filtration Technology

To maintain occupational safety, advanced solder smoke fume extractors are engineered to capture contaminants at the source. These systems use high-efficiency filtration to remove harmful particles before they circulate in the environment. Technologies such as activated carbon filters and HEPA filtration are designed to trap gases as well as particulate matter, ensuring clean and breathable air throughout the workplace.

Understanding the capabilities of solder smoke fume extractors is critical for businesses focused on compliance, operational efficiency, and employee well-being. These systems not only improve air quality but also help reduce absenteeism and health-related liabilities.

Why Air Filtration Is a Critical Investment

The adoption of efficient air extraction systems is not simply optional, it is a strategic business decision. Poor air quality impacts productivity, increases downtime, and elevates health risks. Professional extraction systems provide precise airflow control, adjustable filtration settings, and maintain consistent air purity levels across workstations.

Health Benefits That Protect Your Workforce

Investing in professional fume extraction supports long-term occupational health. Clean air contributes to improved focus, reduced fatigue, and enhanced cognitive performance. Employees are more likely to perform at their best when working in environments free from airborne contaminants. For industries that rely on precision and safety, this is a non-negotiable advantage.

Enhancing Workplace Safety Standards

In addition to health benefits, implementing professional smoke extraction solutions ensures adherence to workplace safety regulations. Industrial environments are increasingly being monitored for indoor air pollutants. Proper extraction demonstrates proactive compliance and reduces the risk of inspections, penalties, or corrective mandates.

The Science of Prevention

Scientific studies confirm that capturing smoke at the source is significantly more effective than general ventilation alone. Professional-grade extractors provide immediate removal of contaminants, ensuring that harmful particles never become part of the breathable environment.

Conclusion

Solder smoke may be invisible to the eye, but its impact on health and workplace air quality is undeniably significant. Proactively extracting fumes at the source with professional-grade systems ensures a safer, cleaner, and more productive environment for employees. By prioritizing advanced filtration technology, businesses can protect their workforce and enhance operational performance without compromise.